About Us

The argument in favor of using filler text goes something like this: If you use real content in the Consulting Process, anytime you reach a review point you’ll end up reviewing and negotiating the content itself and not the design.

ConsultationContact Info

- Chicago 12, Melborne City, USA

- (111) 111-111-1111

- builder@gmail.com

- Week Days: 09.00 to 18.00 Sunday: Closed

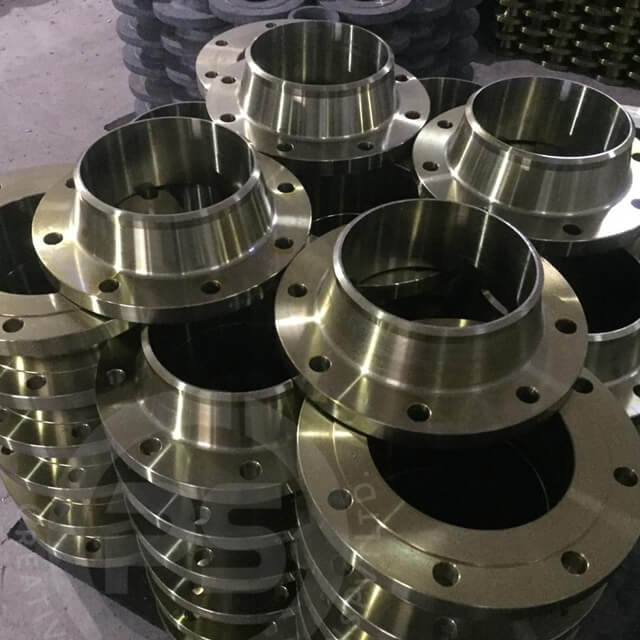

Everything You Need to Know About Alloy Steel F92 Flanges

At Sandvik, we specialize in delivering high-quality piping solutions for demanding industries. One of our flagship offerings is the Alloy Steel F92 Flanges, known for their superior strength, corrosion resistance, and performance in high-temperature environments. Whether you're running a refinery, power plant, or petrochemical facility, understanding the value of these flanges can help you make smarter decisions for your operations.

So, what exactly is an Alloy Steel F92 Flange? These are forged or cast components used to connect pipes, valves, pumps, and other equipment in a piping system. What sets F92 apart is its composition—a martensitic alloy containing chromium, molybdenum, and nitrogen. It’s part of the ASTM A182 specification and designed for high-pressure, high-temperature services. The F92 grade offers excellent mechanical strength, thermal stability, and resistance to creep deformation, making it ideal for extreme service conditions.

There are several benefits to using Alloy Steel F92 Flanges. First, they provide outstanding corrosion and oxidation resistance in both acidic and high-temperature environments. Second, they offer excellent mechanical strength and toughness, which is crucial in systems where safety and durability are non-negotiable. Third, their thermal stability allows for efficient performance in heat-intensive applications, reducing the risk of system failure or unplanned downtime.

Sandvik is one of the top Alloy Steel F92 Flanges Manufacturers known for precision engineering and strict adherence to global standards like ASME, ASTM, and API. We ensure that each product is thoroughly tested to meet the expectations of high-performance industries around the world.

These flanges are widely used across multiple industries. In the oil and gas sector, they connect pipelines transporting crude and refined products under extreme pressure and temperature. In power generation, especially in thermal and nuclear plants, they hold up against high stress and thermal cycling. The chemical industry relies on them for resistance against harsh substances, while water treatment plants use them for durability and longevity in corrosive environments. Even aerospace and marine engineering sectors trust F92 flanges for critical joints and connections.

Sandvik is also a leading Alloy Steel F92 Flanges Suppliers catering to clients with custom dimensions, finishes, and pressure classes. Our team ensures timely delivery and technical support, no matter the complexity of your project.

There are several types of Alloy Steel F92 Flanges available, each designed for specific applications:

Weld Neck Flanges: Designed for high-pressure applications, these flanges are butt-welded to the pipe for strong, leak-proof connections.

Slip-On Flanges: Easy to install and cost-effective, ideal for low-pressure applications where welding on both sides is possible.

Blind Flanges: Used to seal off piping systems or pressure vessel openings, suitable for pressure testing and future expansion.

Socket Weld Flanges: Best for small-bore piping systems where high leakage integrity and strength are needed.

Lap Joint Flanges: Paired with stub ends, ideal for systems that require frequent dismantling for inspection or cleaning.

As trusted Alloy Steel F92 Flanges Stockists, Sandvik maintains a vast inventory to ensure quick turnaround times for urgent orders. Our warehouse network supports global logistics, minimizing delays and maximizing efficiency.

Our commitment to quality and reliability has made Sandvik a preferred choice among international Alloy Steel F92 Flanges Exporters. From standard sizes to custom specifications, we provide flanges that meet the critical demands of modern engineering systems. Contact us today to learn how we can support your next big project.

Specification of Alloy Steel F92 Flanges

| Alloy Steel Flanges Specification : | ASTM A182 / ASME SA182 |

|---|---|

| Dimension Standard : | ANSI/ASME B16.5, B 16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, etc. |

| Standard : | ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, etc. |

| Size : | 1/2" (15 NB) to 48" (1200NB) |

| Class / Pressure : | 150#, 300#, 600#, 900#, 1500#, 2500#, PN6, PN10, PN16, PN25, PN40, PN64 etc. |

| Flange Face Type : | Flate Face (FF), Raised Face (RF), Ring Type Joint (RTJ) |

| DIN Flanges : | DIN 2527, 2566, 2573, 2576, 2641,2642, 2655, 2656, 2627, 2628, 2629, 2631, 2632, 2633, 2634, 2635, 2636, 2637,2638, 2673. |

| JIS Flanges : | JIS B2220 5K, JIS B2220 10K, JIS B2220 16K, JIS B2220 20K |

| BS Flanges : | BS4504 PN 6, BS 4504 PN 10, BS4504 PN 16, BS4504 PN 25, BS4504 PN 40, BS 4504 PN 64, BS 4504 PN 100, BS 4504 PN 160, BS 4504 PN 250, BS 10, BS Table D, BS Table E, BS Table F, BS Table H. |