About Us

The argument in favor of using filler text goes something like this: If you use real content in the Consulting Process, anytime you reach a review point you’ll end up reviewing and negotiating the content itself and not the design.

ConsultationContact Info

- Chicago 12, Melborne City, USA

- (111) 111-111-1111

- builder@gmail.com

- Week Days: 09.00 to 18.00 Sunday: Closed

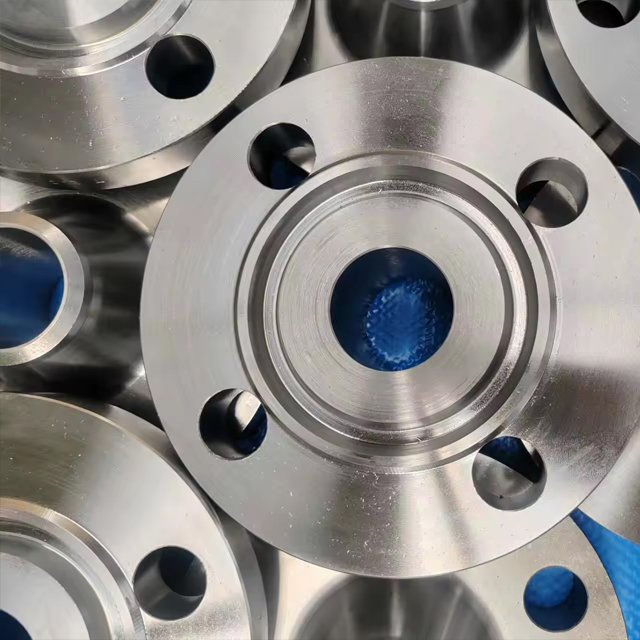

Everything You Need to Know About Duplex Steel S31803/S32205 Flanges

When it comes to high-performance piping components, Duplex Steel S31803/S32205 Flanges stand out for their exceptional mechanical strength, corrosion resistance, and cost efficiency. At Sandvik, we provide industry-grade duplex steel flanges that meet demanding requirements across oil & gas, petrochemical, power generation, and marine sectors. These flanges are designed for environments where durability and reliability are not optional—they’re essential.

What is Duplex Steel S31803/S32205 Flanges? These flanges are crafted from duplex stainless steel, primarily UNS S31803 and UNS S32205. The material is a 50/50 mix of austenitic and ferritic stainless steel structures, offering a balance of strength and corrosion resistance. S32205 is an improved version of S31803, with tighter composition limits to enhance corrosion resistance, especially against stress corrosion cracking and pitting. These flanges are widely used in pipeline connections, ensuring a leak-proof and pressure-resistant system.

Sandvik is one of the most trusted Duplex Steel S31803/S32205 Flanges Manufacturers, offering top-notch products that comply with international standards like ASME, ASTM, and EN. Our flanges undergo rigorous testing and inspection to ensure maximum performance even under extreme pressure and temperature conditions.

Advantages of Duplex Steel S31803/S32205 Flanges are numerous. First, they have double the strength of conventional austenitic stainless steel flanges, which allows for thinner wall designs and lower weight. Second, their resistance to general corrosion, crevice corrosion, and erosion makes them ideal for aggressive chemical environments. Third, they perform exceptionally well in marine and offshore conditions due to their high resistance to chloride stress corrosion cracking. Finally, duplex steel flanges offer a longer service life, which reduces maintenance and downtime costs.

As experienced Duplex Steel S31803/S32205 Flanges Suppliers, we at Sandvik serve a broad range of industries. In oil and gas, these flanges are used for pipelines, subsea equipment, and processing facilities. In petrochemicals, they’re used for heat exchangers, reactors, and pressure vessels. In marine industries, they are found in desalination plants and shipbuilding applications. Power generation and chemical processing industries also rely on them for their resilience under extreme operating conditions.

We are one of the leading Duplex Steel S31803/S32205 Flanges Stockists, maintaining a comprehensive inventory that includes various flange types. Here’s a quick look:

Weld Neck Flanges: Ideal for high-pressure applications. Their long tapered hub provides extra strength.

Slip-On Flanges: Easy to install and weld. Perfect for low-pressure, non-critical applications.

Blind Flanges: Used to close the end of a piping system. They allow for easy access for inspection.

Socket Weld Flanges: Designed for small-diameter, high-pressure pipes. They offer a strong, leak-proof joint.

Threaded Flanges: No welding required, making them suitable for hazardous areas where welding is not permitted.

Lap Joint Flanges: Used with stub ends, allowing easy disassembly for inspection or cleaning.

As one of the most reliable Duplex Steel S31803/S32205 Flanges Exporters, Sandvik ensures timely delivery and global shipping. We supply to markets across Asia, Europe, the Middle East, and North America. Every shipment is packed to preserve quality and meet client specifications.

If you're searching for robust, corrosion-resistant flanges with proven performance in harsh environments, Duplex Steel S31803/S32205 Flanges from Sandvik are the smart choice. Contact us today to get the best in class engineering solutions tailored to your industry needs.

Specification of Duplex Steel S31803/S32205 Flanges

| Duplex Stainless Steel Flanges Specification : | ASTM A182 / ASME SA182 |

|---|---|

| Dimension Standard : | ANSI/ASME B16.5, B 16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, etc. |

| Standard : | ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, etc. |

| Size : | 1/2" (15 NB) to 48" (1200NB) |

| Class / Pressure : | 150#, 300#, 600#, 900#, 1500#, 2500#, PN6, PN10, PN16, PN25, PN40, PN64 etc. |

| Flange Face Type : | Flate Face (FF), Raised Face (RF), Ring Type Joint (RTJ) |

| DIN Flanges : | DIN 2527, 2566, 2573, 2576, 2641,2642, 2655, 2656, 2627, 2628, 2629, 2631, 2632, 2633, 2634, 2635, 2636, 2637,2638, 2673. |

| JIS Flanges : | JIS B2220 5K, JIS B2220 10K, JIS B2220 16K, JIS B2220 20K |

| BS Flanges : | BS4504 PN 6, BS 4504 PN 10, BS4504 PN 16, BS4504 PN 25, BS4504 PN 40, BS 4504 PN 64, BS 4504 PN 100, BS 4504 PN 160, BS 4504 PN 250, BS 10, BS Table D, BS Table E, BS Table F, BS Table H. |

Equivalent Grades of Duplex Steel S31803/S32205 Flanges

| STANDARD | WNR. |

|---|---|

| Duplex S31803 / S32205 | 1.4462 |

Chemical Composition of Duplex Steel S31803/S32205 Flanges

| Grade | Common Name | C% | Mn% | Si% | P% | S% | Cr% | Ni% | Mo% | N% |

|---|---|---|---|---|---|---|---|---|---|---|

| 2205 | S31803 | 0.030 | 2.00 | 1.00 | 0.030 | 0.020 | 21.0-23.0 | 4.5-6.5 | 2.5-3.5 | 0.08-0.20 |

| 2205 | S32205 | 0.030 | 2.00 | 1.00 | 0.030 | 0.020 | 22.0-23.0 | 4.5-6.5 | 3.0-3.5 | 0.14-0.20 |

Mechanical Properties of Duplex Steel S31803/S32205 Flanges

| Tensile strength | 620MPa min | Density | 7,805kg/m3 |

|---|---|---|---|

| Yield strength | 450MPa mi | Elastic modulus | 200GPa |