About Us

The argument in favor of using filler text goes something like this: If you use real content in the Consulting Process, anytime you reach a review point you’ll end up reviewing and negotiating the content itself and not the design.

ConsultationContact Info

- Chicago 12, Melborne City, USA

- (111) 111-111-1111

- builder@gmail.com

- Week Days: 09.00 to 18.00 Sunday: Closed

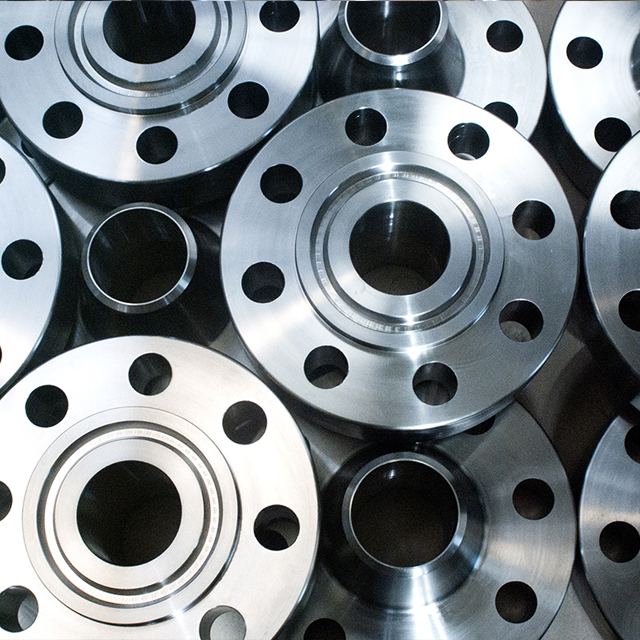

Top Benefits and Applications of Titanium Gr 2 Flanges – A Comprehensive Guide by Sandvik

At Sandvik, we understand the growing demand for high-performance materials in critical industrial operations. One such material that continues to prove its worth is Titanium Grade 2. Our Titanium Gr 2 Flanges Manufacturers produce components that combine strength, corrosion resistance, and long-term durability—ideal for industries that demand peak performance without compromise.

What is Titanium Gr 2 Flange? Simply put, Titanium Gr 2 Flanges are pipe connectors made from commercially pure titanium, Grade 2. This grade is known for its excellent corrosion resistance, moderate strength, and superior weldability. These properties make it the go-to choice in marine, chemical processing, and aerospace industries where exposure to harsh environments is common.

As leading Titanium Gr 2 Flanges Suppliers, Sandvik ensures our products meet strict international standards. Titanium Gr 2 is a non-alloyed titanium that retains all its natural corrosion-resistant properties while being easier to form and fabricate than higher grades. It's non-toxic, making it suitable for medical and food processing applications as well.

The advantages of using Titanium Gr 2 Flanges are numerous. First, their high resistance to oxidizing environments, including chlorides, seawater, and most acids, ensures extended service life. Second, their lightweight profile—45% lighter than steel—makes installation easier and reduces structural load. Third, Titanium Gr 2 has excellent strength-to-weight ratio and withstands temperatures up to 315°C, making it reliable in extreme conditions. These flanges are also low-maintenance and offer long-term cost savings, especially in corrosive environments.

As experienced Titanium Gr 2 Flanges Stockists, Sandvik supports industries ranging from petrochemical to pharmaceutical. In aerospace, these flanges are essential for lightweight, corrosion-resistant piping systems. In marine and offshore, they combat aggressive saltwater exposure. Chemical plants depend on them for their ability to withstand harsh acids and alkalis. Even the power generation sector uses them for their endurance under high pressure and temperature fluctuations.

There are several types of Titanium Gr 2 Flanges available, each suited to different applications. Weld Neck Flanges are used in high-pressure environments due to their long tapered hub that offers reinforcement. Slip-On Flanges are ideal for lower pressure systems and allow for quick installation. Blind Flanges are used to seal the end of pipes or valves, often in pressure testing or future expansion. Socket Weld Flanges are perfect for small-diameter high-pressure piping. Threaded Flanges are used where welding is not practical, often in low-pressure non-critical applications. Each flange type is carefully designed to optimize performance in its specific use-case.

As global Titanium Gr 2 Flanges Exporters, Sandvik delivers across borders with a reputation for quality and consistency. Our commitment to customer satisfaction and adherence to international standards makes us a trusted name in the titanium flange market. Whether you need standard or custom specifications, our team ensures on-time delivery and top-tier product integrity.

If you're sourcing durable and efficient flange solutions, Titanium Gr 2 is a smart investment. And with Sandvik, you’re not just buying a product—you’re securing performance, reliability, and long-term value.

Specification of Titanium Gr 2 Flanges

| Titanium Flanges Specification : | ASTM B363 / ASME SB363 |

|---|---|

| Dimension Standard : | ANSI/ASME B16.5, B 16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, etc. |

| Standard : | ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, etc. |

| Size : | 1/2" (15 NB) to 48" (1200NB) |

| Class / Pressure : | 150#, 300#, 600#, 900#, 1500#, 2500#, PN6, PN10, PN16, PN25, PN40, PN64 etc. |

| Flange Face Type : | Flate Face (FF), Raised Face (RF), Ring Type Joint (RTJ) |

| DIN Flanges : | DIN 2527, 2566, 2573, 2576, 2641,2642, 2655, 2656, 2627, 2628, 2629, 2631, 2632, 2633, 2634, 2635, 2636, 2637,2638, 2673. |

| JIS Flanges : | JIS B2220 5K, JIS B2220 10K, JIS B2220 16K, JIS B2220 20K |

| BS Flanges : | BS4504 PN 6, BS 4504 PN 10, BS4504 PN 16, BS4504 PN 25, BS4504 PN 40, BS 4504 PN 64, BS 4504 PN 100, BS 4504 PN 160, BS 4504 PN 250, BS 10, BS Table D, BS Table E, BS Table F, BS Table H. |

Equivalent Grades of Titanium Gr 2 Flanges

| STANDARD | UNS | WNR. |

|---|---|---|

| Titanium Gr 2 | R50400 | 3.7035 |

Chemical Composition of Titanium Gr 2 Flanges

| C | Fe | H | N | O | Ti |

|---|---|---|---|---|---|

| 0.1 | 0.3 | 0.015 | 0.03 | 0.25 | 99.2 |

Mechanical Properties of Titanium Gr 2 Flanges

| Grade | Tensile (ksi) | Yield Strength (ksi) | Hardness |

|---|---|---|---|

| Titanium Gr 2 | 50 | 40 | 14.9 |