About Us

The argument in favor of using filler text goes something like this: If you use real content in the Consulting Process, anytime you reach a review point you’ll end up reviewing and negotiating the content itself and not the design.

ConsultationContact Info

- Chicago 12, Melborne City, USA

- (111) 111-111-1111

- builder@gmail.com

- Week Days: 09.00 to 18.00 Sunday: Closed

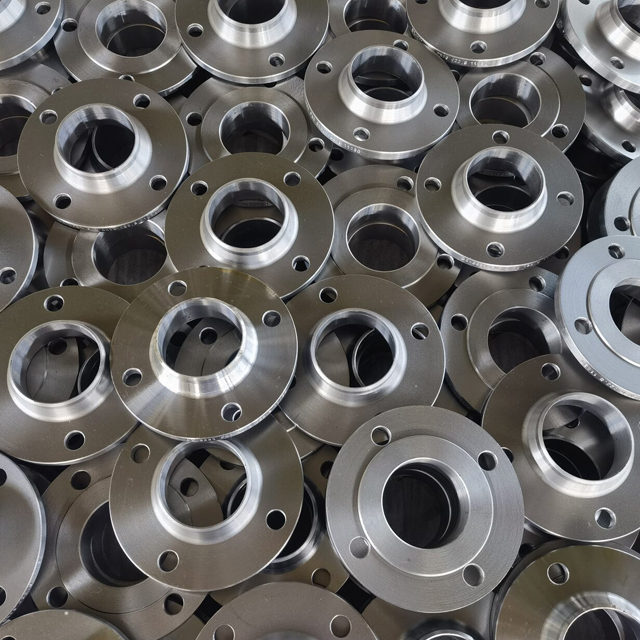

High-Performance and Corrosion-Resistant: A Complete Guide to Titanium Gr 5 Flanges by Sandvik

Titanium Gr 5 Flanges are known for their exceptional strength-to-weight ratio, corrosion resistance, and ability to withstand extreme environments. At Sandvik, we deliver high-quality flanges crafted from Grade 5 Titanium (Ti-6Al-4V), the most widely used titanium alloy in industrial applications. These flanges are designed to meet the performance needs of high-pressure systems in industries ranging from aerospace to marine engineering.

So, what is Titanium Gr 5 Flanges? These are flange fittings manufactured using Grade 5 Titanium, a titanium alloy containing 6% aluminum and 4% vanadium. This alloy is known for its superior mechanical properties, excellent corrosion resistance, and high thermal stability. Titanium Gr 5 is often the first choice for critical systems where both strength and corrosion resistance are non-negotiable. Flanges made from this material are not only reliable but also lightweight and durable, making them a strategic asset for complex assemblies.

One of the major advantages of Titanium Gr 5 Flanges is their resistance to corrosion in aggressive environments, including seawater, oxidizing acids, and chloride-rich media. They also offer outstanding mechanical strength, especially at high temperatures, and have a long service life with minimal maintenance. Additionally, these flanges are biocompatible, which opens their use to medical and chemical industries. The lightweight nature of titanium also helps in reducing the overall weight of assemblies without compromising strength.

As leading Titanium Gr 5 Flanges Manufacturers, Sandvik ensures each flange meets global standards such as ASTM B381 and ASME specifications. Our flanges are precision-engineered to serve a variety of industrial applications where reliability and material integrity are paramount.

Applications and uses of Titanium Gr 5 Flanges span across numerous sectors. In the aerospace industry, they are used in engine components, airframes, and hydraulic systems due to their excellent strength-to-weight ratio. The chemical and petrochemical industries rely on them for resistance to aggressive chemicals and corrosion. Marine engineers favor them for shipbuilding and offshore oil rigs. In the medical sector, these flanges are used in surgical implants and instruments because of their biocompatibility. Power generation, desalination plants, and automotive performance systems also benefit from their robust properties.

Sandvik is a trusted name among global Titanium Gr 5 Flanges Suppliers, providing flanges that consistently meet the critical performance and safety benchmarks of our clients’ industries.

There are various types of Titanium Gr 5 Flanges available, each designed for specific operational needs:

Weld Neck Flanges – Ideal for high-pressure environments and long-term use due to their tapered hub that adds strength.

Slip-On Flanges – Easy to install and economical, suitable for low-pressure and non-critical connections.

Blind Flanges – Used to seal pipe ends or pressure vessel openings, providing complete isolation.

Socket Weld Flanges – Designed for small-diameter, high-pressure piping where leakage strength is crucial.

Threaded Flanges – Useful in systems where welding is not feasible; commonly used in low-pressure applications.

Lap Joint Flanges – Ideal for systems requiring frequent disassembly, used with stub ends for better alignment.

Orifice Flanges – Integrated with flow measurement systems, allowing precise fluid control.

As recognized Titanium Gr 5 Flanges Stockists, Sandvik offers immediate availability and global shipping for urgent project requirements. Our extensive inventory and quality assurance make us the go-to solution for critical component sourcing.

Sandvik also ranks among the most reliable Titanium Gr 5 Flanges Exporters worldwide. We adhere to stringent quality control protocols and ensure each product meets international certification and compliance standards. Whether your project demands lightweight solutions or corrosion-proof integrity, Sandvik delivers excellence every time.

Specification of Titanium Gr 5 Flanges

| Titanium Flanges Specification : | ASTM B363 / ASME SB363 |

|---|---|

| Dimension Standard : | ANSI/ASME B16.5, B 16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, etc. |

| Standard : | ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, etc. |

| Size : | 1/2" (15 NB) to 48" (1200NB) |

| Class / Pressure : | 150#, 300#, 600#, 900#, 1500#, 2500#, PN6, PN10, PN16, PN25, PN40, PN64 etc. |

| Flange Face Type : | Flate Face (FF), Raised Face (RF), Ring Type Joint (RTJ) |

| DIN Flanges : | DIN 2527, 2566, 2573, 2576, 2641,2642, 2655, 2656, 2627, 2628, 2629, 2631, 2632, 2633, 2634, 2635, 2636, 2637,2638, 2673. |

| JIS Flanges : | JIS B2220 5K, JIS B2220 10K, JIS B2220 16K, JIS B2220 20K |

| BS Flanges : | BS4504 PN 6, BS 4504 PN 10, BS4504 PN 16, BS4504 PN 25, BS4504 PN 40, BS 4504 PN 64, BS 4504 PN 100, BS 4504 PN 160, BS 4504 PN 250, BS 10, BS Table D, BS Table E, BS Table F, BS Table H. |

Equivalent Grades of Titanium Gr 5 Flanges

| STANDARD | UNS | WNR. |

|---|---|---|

| Titanium Gr 5 | R56400 | 3.7165 |

Chemical Composition of Titanium Gr 5 Flanges

| Al | Fe | O | Ti | V |

|---|---|---|---|---|

| 6 | 0.25 | 0.2 | 90 | 4 |

Mechanical Properties of Titanium Gr 5 Flanges

| Element | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

|---|---|---|---|---|---|

| Titanium Gr. 5 | 4.43 g/cm3 | 1632 °C (2970 °F) | Psi – 138000 , MPa – 950 | Psi – 128000 , MPa – 880 | 14 % |